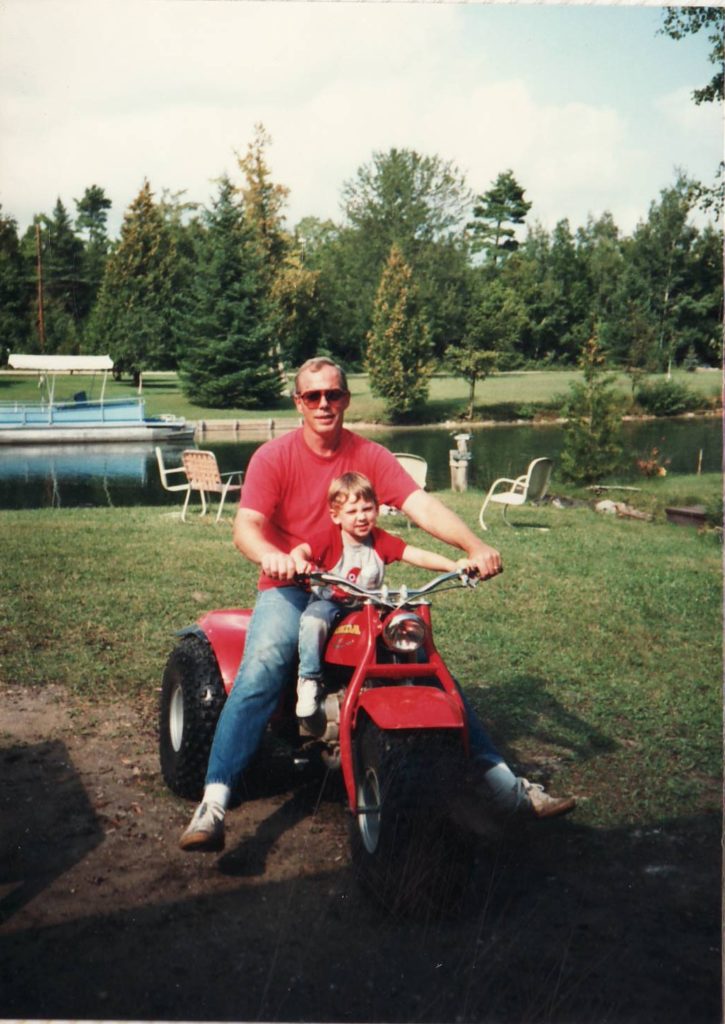

For 4 decades, our Honda ATC 90 has loyally served the family, providing 4 season fun and utility for all ages. For the past few years, however, it’s grown harder to start. This past Sunday, I towed the machine down-state for some long overdue repairs.

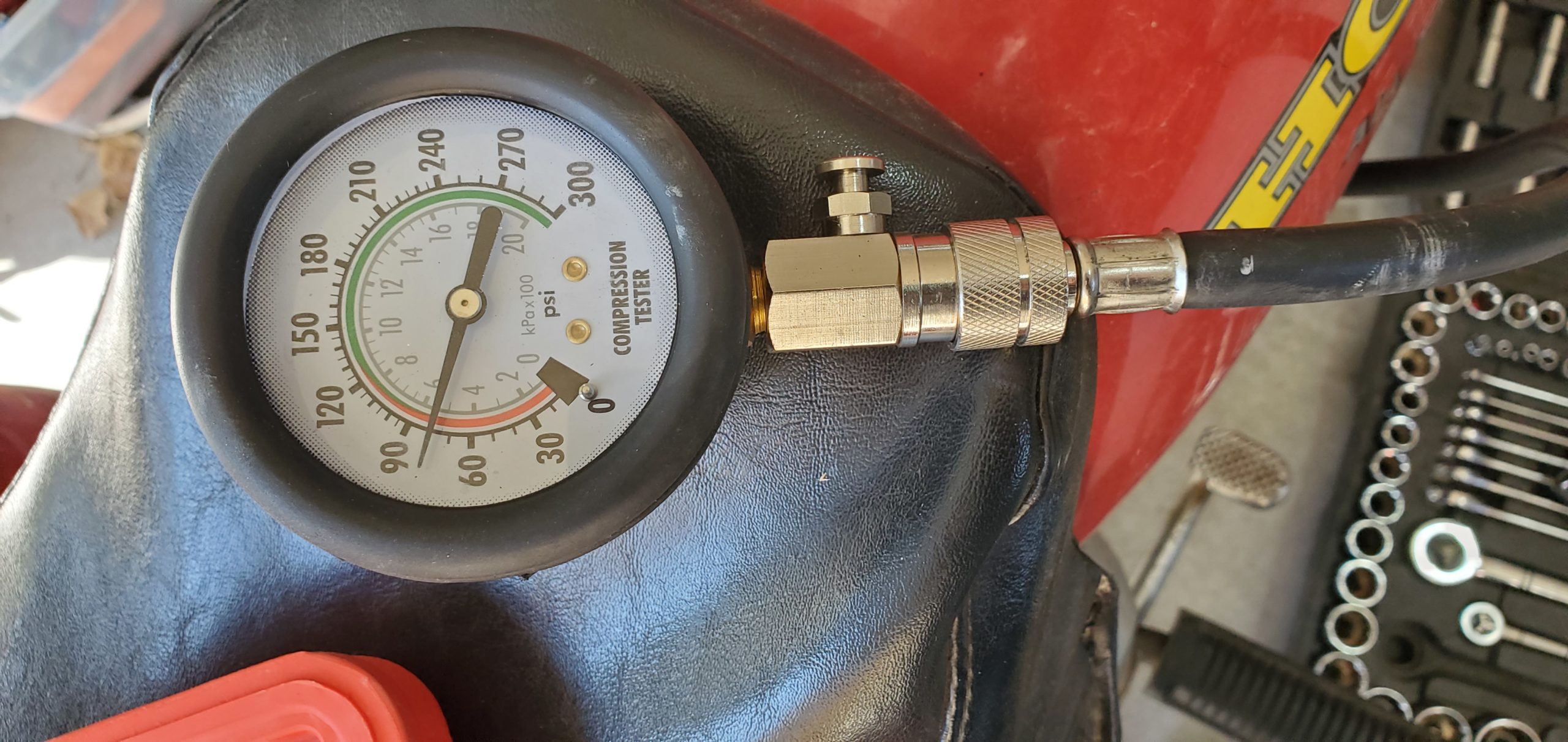

When diagnosing engine issues, the best place to start is with a compression test. I suspected that cylinder compression was not up to spec, so a compression test was the first step. The specification is 142 – 170 psi. I connected the compression tester, opened the throttle completely, and pulled the starter rope several times. The gauge topped out at 80 psi … not great, as expected. The engine would need some top-end attention.

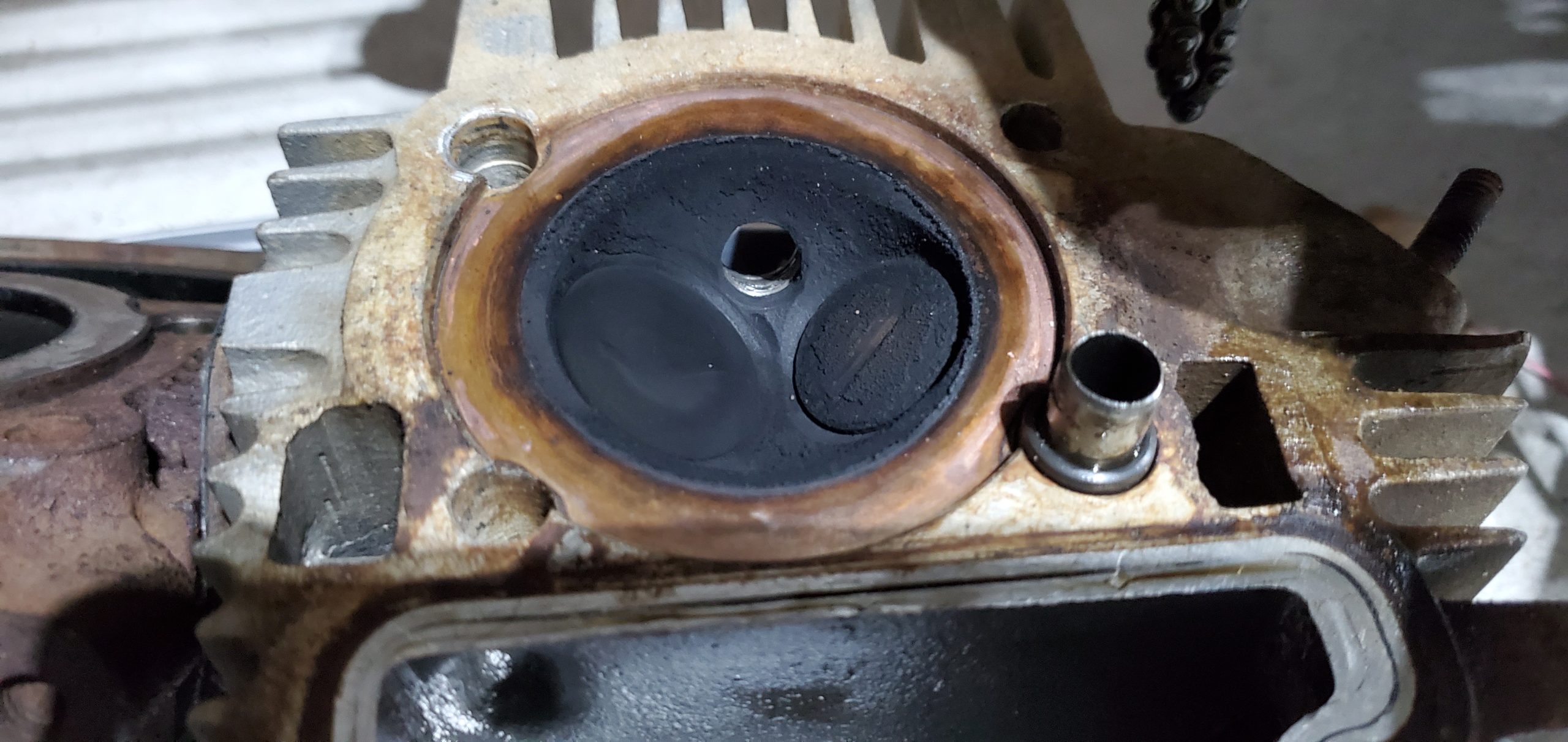

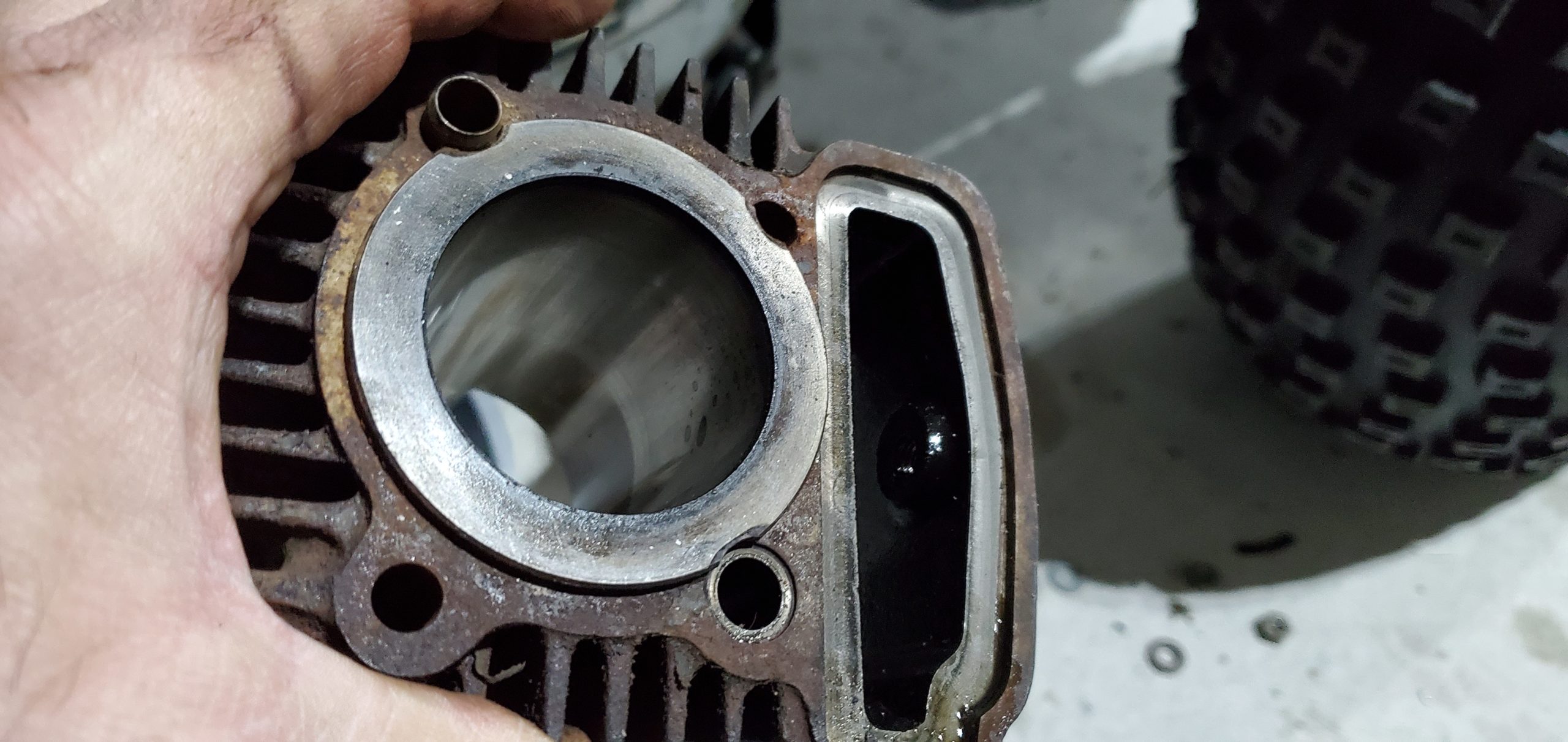

I pulled the engine head and cylinder for closer inspection. A late evening meeting with work put an end to the analysis, but I was able to get the top end disassembled. As expected, the cylinder head combustion chamber had a heavy carbon build-up. The cylinder didn’t look too bad, and the piston rings were not frozen into the grooves. I’ll look at the parts more closely over the next few days and determine what I need to order. I have already ordered a new exhaust pipe and muffler, mounting studs for the exhaust, a gasket set, and a few miscellaneous parts. Not too bad. I have no plans on tearing apart the bottom end of the engine at this time.

I removed the piston and took measurements. Both the piston and the cylinder are within spec, and visually look good. Therefore, I currently plan on reusing the piston. I’ll lightly hone the cylinder prior to assembly. The valves were heavily caked with carbon deposits, but can be cleaned, lapped and used again.

This is a good start toward getting the ATC 90 back in service.